MASONRY FOUNDATIONS [ Load Bearing Structures ]

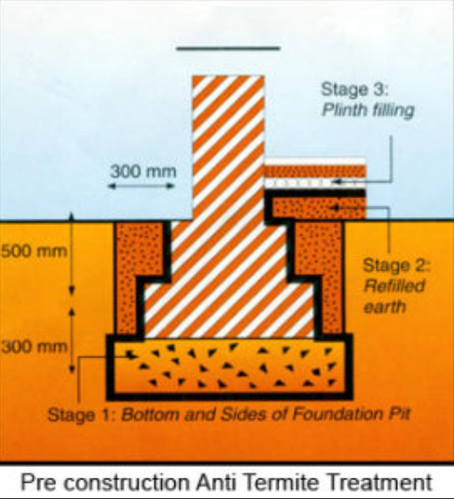

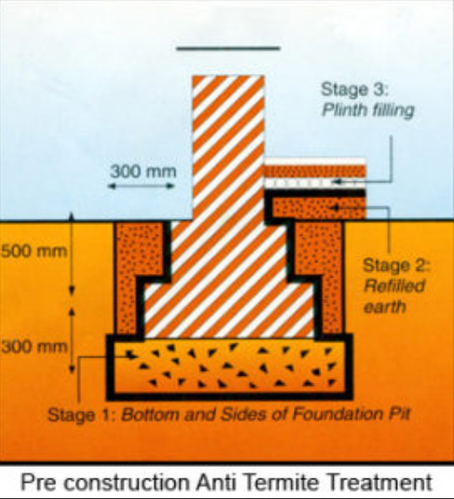

Pre-Construction Anti Termite Treatment Process at the various stages of construction as per IS / and as recommended by the chemical manufacturer to safeguard the building against termite including execution and submission of guarantee for a period of 10 years.

Chemical Composition

For anti-termite treatment chemicals used as per IS 8944 CHLORPYRIPHOS 20 % EC @ 1 % concentration in aqueous emulsion, IMIDACLOPRID 30.5% SC @ 0.075 % as per IS 8944.

Soil Treatment Process

For the anti-termite treatment of soil process can be done manually by the Hand operated pressure pump or it can be also done by the electrically operated pump shall be used for uniform spraying of the chemical from graduated containers.

Specified quantity of chemical should be used for the required area during the operation. (In the event of waterlogging of foundation, the water shall be pumped out and the chemical emulsion applied when the soil is absorbent.)

Trenches made for foundation of Masonry walls or Basement

The bottom surface of the foundation and the foundation sides up to a height of about 300 mm of the excavations made from masonry foundations and basements shall be treated with the chemical at the rate of 5 litres at per square meter of surface area.

Vertical Backfilled Soil along masonry Foundation/ retaining wall

After the masonry foundations and the retaining wall of the basements come up; the backfill in contact with the foundation structure shall be treated at the rate of 7.5 litres per square meter of the vertical surface of the sub-structure for each side of the foundation.

If water is sprayed or watering is done for ramming the earth fill, the chemical treatment shall be carried out only after the ramming operation is done by rodding the earth at 150 mm centers close to parallel to the wall surface and anti-termite spraying should be done by the chemical emulsion. After the treatment, the soil should be properly compacted in place.

The earth filling is done in layers and the treatment shall be carried out in similar stages. The chemical emulsion shall be done on the masonry surfaces so that the earth in contact with these surfaces is well treated with the chemical.

Top Surface of Plinth Filling

The top surface of the consolidated earth within plinth walls shall be treated with chemical emulsion at the rate of 5 l/m2 of the surface before the sand bed or subgrade laid. This treatment shall also be carried out on DPC provided on plinth wall. If the filled earth has been well compacted and it not letting the emulsion to seep into the , holes up to 50 to 75 mm deep at 150 mm centres both ways may be made with 12 mm diameter mild steel rod on the surface to let the chemical to sweep in the soil with the chemical emulsion.

Junction of the wall and the floor

For the anti-termite treatment at the junction of the wall we have to do some care to establish continuity of the vertical chemical barrier on inner wall surface from ground level (where it had stopped with the treatment described in) up to level of the filled earth surface.

For the anti-termite treatment at the junction of the wall is carried out by a small channel 30 mm x 30 mm shall be made at all the junction of wall and columns with the floor (this has to be done before laying the sub-grade) the rod holes made in the channel up to the ground level 150 mm apart and the iron rod should be moved in backward and forward to create hole in the earth and chemical emulsion poured along the wall at the rate of 7.5 l/m2 of vertical wall or at the column surface so chemical will reach to the soil right to the bottom. The soil should be compacted well after the Anti-termite process is complete.

Soil along External Perimeter of Building:

After the building work is complete, the earth which is along the external perimeter of the building should be rodded at intervals of 150 mm and to a depth of 300 mm. The rods should be moved in the earth in backward and forward direction parallel to the wall to create the holes in the compacted earth and chemical emulsion is poured along the wall at the rate of 7.5 liter per square meter of the vertical surface. After the treatment the earth should be compacted.

If extra earth filling outside the building then it should be done on completion of building, after that only anti-termite of that area should be carried out If the earth filling is more than 300 mm, the external perimeter treatment should be done to the full depth of filling up to the ground level so as to ensure chemical reached at the bottom of the surface.

Soil Surrounding Pipes, Wastes and Conduits

When we do the external work such as pipes, wastes and conduits enter the soil inside area of the foundations, soil around the point of entry shall be loosened around each such pipe, waste or conduit for a distance of 150 mm and to a depth of 75 mm before treatment is started. When the pipes, wastes and conduits enter the soil external to the foundation, they shall be similarly treated at a distance of over 300 mm unless they stand clear of the walls of the building by about 75 mm.

Expansion Joints

The soil beneath these joints should receive special attention when the treatment under is carried out. This treatment should be supplemented by treating through the expansion joints after the sub-grade has been laid, at the rate of 2 liters per linear meter.

RCC FOUNDATION [ Basement Buildings ]

For the treatment of RCC basement building after the excavation for basement is complete and before laying soling and PCC. The anti-termite treatment shall be carried out in the following stages.

Soil below raft

Before laying the rubble soling and PCC, the compacted and levelled soil shall be treated at 5 litre/sqm.

Soil along the retaining wall

The soil retained by the walls (soil coming in contact with retaining wall) shall be treated at the rate of 7.5 litre per square meter of the vertical. The treatment shall follow the backfilling as backfilling is done in stages of 30 cms but not to exceed a depth of 1 meter. Rodding may be carried out to facilitate the treatment.

Soil along External Perimeter of Building

Pre-Construction Anti Termite treatment of Soil along External Perimeter of Building after the building is complete; the earth along the external perimeter of the building should be pressed at intervals of 150 mm and to a depth of 300 mm.

The rods should be applied backward and forward parallel to the wall to create a hole in the earth and chemical emulsion poured along the wall at the rate of 7.5 liter per square meter of the vertical surface. After the treatment, the earth should be compacted well. If the filling of earth to be done outside the building then chemichal treatment should be done after filling and compaction of the soil is complete.

Soil Surrounding Pipes, Wastes and Conduits

When external work such as pipes, wastes and conduits enter the soil, the inside area of the foundations, soil surrounding the point of entry of pipes, wastes and conduits shall be loosened around each such pipe, waste or conduit for a distance of 150 mm and to a depth of 75 mm before anti-termite treatment is started . When pipes, wastes and conduits enter the soil external to the foundation, they shall be similarly treated at a distance of over 300 mm until they stand clear of the walls of the building by about 75 mm.

Measurement Process

Building area in plan shall be measured in Sq. M. based on the treatment provided. For the Measurement of foundation you have to calculate area by Multiplying Length x Depth while for the filling area is is determined by the Length x Width.